Adding fillers to composite HPMC will affect its performance and quality

Adding fillers to composite HPMC will affect its performance and quality. The specific impact depends on the type of filler, particle size, content, and compatibility with HPMC. Here are some common impacts:

Density and Weight: Adding fillers increases the density and weight of composite HPMC, which can affect the product’s volume and appearance.

Flowability: Fillers can affect the flowability of composite HPMC, making it more viscous or sticky, which may impact its application performance and coating effect.

Strength and Hardness: Fillers can increase the strength and hardness of the composite material, altering its physical properties, which may affect its performance in specific applications.

Weather Resistance: Fillers can affect the weather resistance of composite HPMC, making it more durable or wear-resistant, or causing chemical reactions in specific environments, leading to degradation or discoloration.

Cost: Adding fillers can increase the product’s cost, especially if the fillers are expensive or require additional processing.

Compatibility: The choice and content of fillers can affect compatibility with HPMC, potentially leading to product non-uniformity or instability, requiring further research and testing.

Therefore, when designing a composite HPMC formulation, it is important to consider the type, content, and compatibility of fillers to ensure the product meets the expected performance and quality requirements.

RuiDaXu Pure HPMC Other Composite HPMC

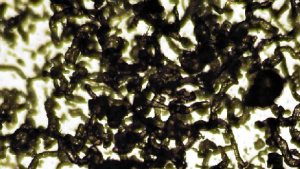

Composite HPMC appears as aggregates under a microscope, while RuiDaXu pure HPMC appears as fibrous and transparent. This observation likely reflects the differences in the microstructure of the two types of HPMC.

Composite HPMC:

Appears as aggregates under a microscope, possibly due to interactions between the fillers or other additives and HPMC, forming granules or clusters. This aggregation may affect the uniformity and transparency of HPMC, making it appear as aggregates under a microscope.

Pure HPMC:

Appears as fibrous and transparent under a microscope, possibly reflecting the crystalline structure and single composition of pure HPMC. The fibrous appearance might be due to HPMC molecules aggregating in solution to form fibrous structures, while the transparency might be due to its high purity and clarity.

Overall, the observation results under a microscope reflect the different microstructures of composite HPMC and pure HPMC. Composite HPMC may form aggregates or clusters due to the presence of additives, while RuiDaXu pure HPMC appears more uniform and transparent due to its fibrous structure.